LPN Management¶

Overview¶

The LPN (License Plate Number) Management system in Zora Tech Logistics Platform provides comprehensive container tracking and management for warehouse operations. LPNs are essential for tracking inventory through all warehouse processes including receiving, putaway, picking, and shipping.

Key Features: - Multiple container types (Tote, Bin, Box, Pallet, Case, Cart, Cage) - Automatic barcode generation or custom barcodes - Real-time capacity tracking (weight, volume, orders) - Inventory container vs operational LPN distinction - Status tracking through entire warehouse lifecycle - Location-based LPN management - Priority-based processing

Table of Contents¶

- Getting Started

- Understanding LPNs

- Accessing LPN Management

- LPN Information Structure

- Creating a New LPN

- LPN Details and Contents

- LPN Status Lifecycle

- Search and Filtering

- LPN Types

- Inventory Containers vs Operational LPNs

- LPN Movements

- Best Practices

- Troubleshooting

Getting Started¶

Prerequisites¶

Before managing LPNs, ensure you have:

- Warehouse Access: Select an active warehouse from the warehouse selector

- Appropriate Permissions: User role with LPN management access

- Container Types Understanding: Knowledge of your warehouse container types

- Barcode Scanners: (Optional) For scanning LPN barcodes

Key Concepts¶

LPN (License Plate Number): A unique identifier for a physical container used in warehouse operations

Inventory Container: An LPN that stores inventory in a fixed location for long-term storage

Operational LPN: An LPN used for temporary operations like picking, packing, or staging

Container Type: Physical container category (Tote, Bin, Box, Pallet, Case, Cart, Cage)

LPN Status: Current state in the warehouse workflow (Available, In Use, At Staging, etc.)

Capacity: Maximum weight, volume, and order limits for an LPN

Priority: Processing priority level from 1 (highest) to 7 (lowest)

Understanding LPNs¶

What is an LPN?¶

An LPN is a licensed container with a unique barcode identifier used to track inventory and orders throughout warehouse operations. Think of it as a tracked bin, box, pallet, or cart that can hold products and move through your warehouse workflows.

LPN Lifecycle¶

- Creation: LPN is created with specific type and capacity

- Available: LPN is ready for use

- Building/In Use: LPN is being filled with inventory or orders

- At Staging: LPN is moved to staging area

- Processing: LPN contents are being processed

- Shipped/Completed: LPN contents shipped, LPN becomes available again

LPN Categories¶

Inventory Containers - Used for long-term inventory storage - Assigned to specific warehouse locations - Status: IN_INVENTORY or INVENTORY_LOCKED - Not actively moving through workflows

Operational LPNs - Used for active warehouse operations - Move through picking, packing, staging workflows - Various statuses based on current operation - Return to AVAILABLE status when empty

Accessing LPN Management¶

Navigation¶

- Click Operations in the left sidebar

- Select LPNs

- Ensure a warehouse is selected in the header

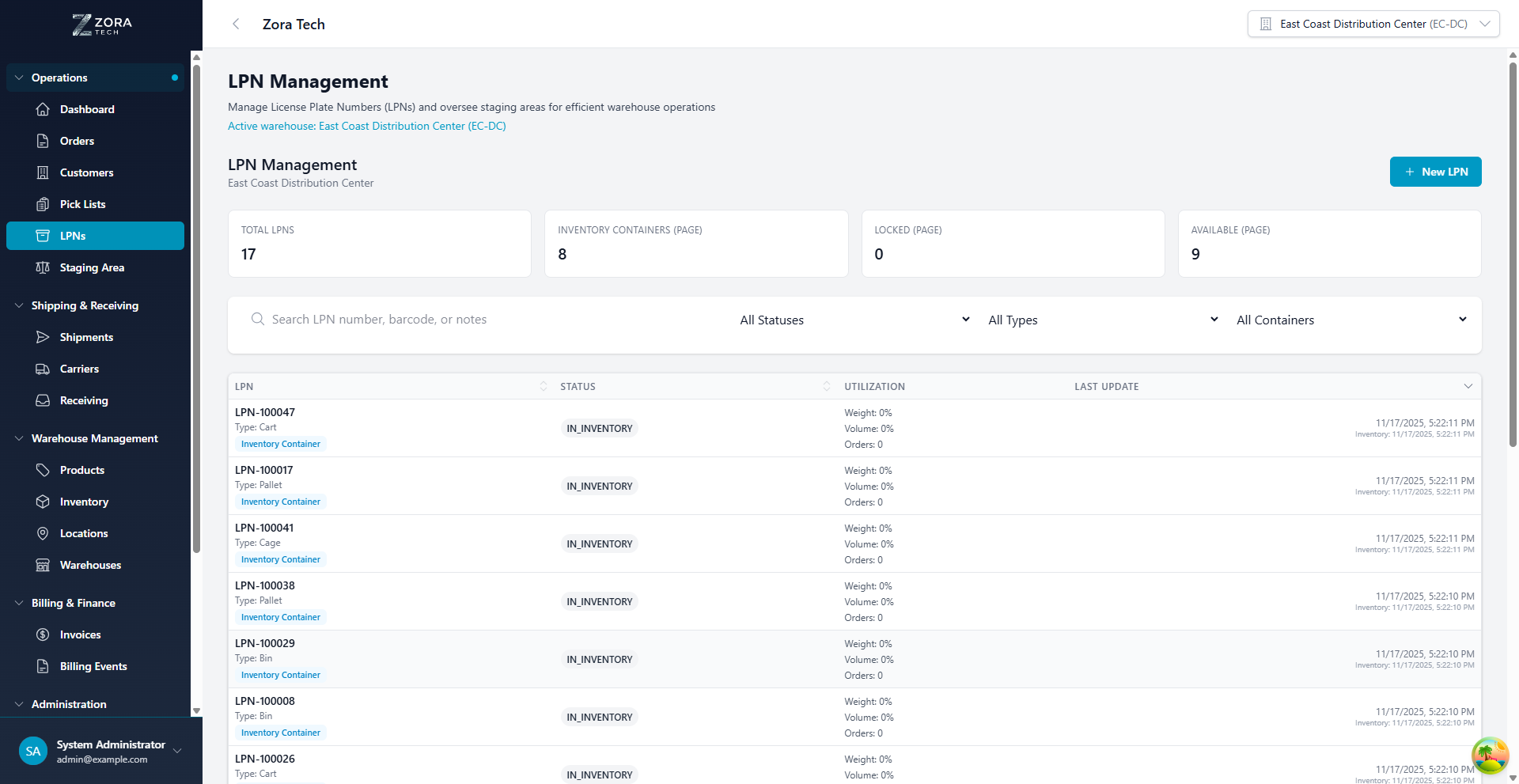

Page Layout¶

The LPN Management page includes:

- Header: Shows warehouse context and total LPN count

- Summary Cards: Quick metrics (Total, Inventory Containers, Locked, Available)

- New LPN Button: Create new LPNs

- Search & Filters: Find LPNs by number, barcode, status, type

- LPN Table: Lists all LPNs with key details and utilization

LPN Information Structure¶

LPN Table Columns¶

| Column | Description |

|---|---|

| LPN | LPN number, type, and inventory container badge |

| Status | Current status badge (Available, In Use, In Inventory, etc.) |

| Utilization | Weight, volume, and order count usage |

| Last Update | Last activity timestamp and inventory update time |

Summary Metrics¶

Total LPNs: All LPNs in the warehouse

Inventory Containers (page): LPNs designated as inventory storage

Locked (page): LPNs with inventory lock status

Available (page): LPNs ready for use in operations

Creating a New LPN¶

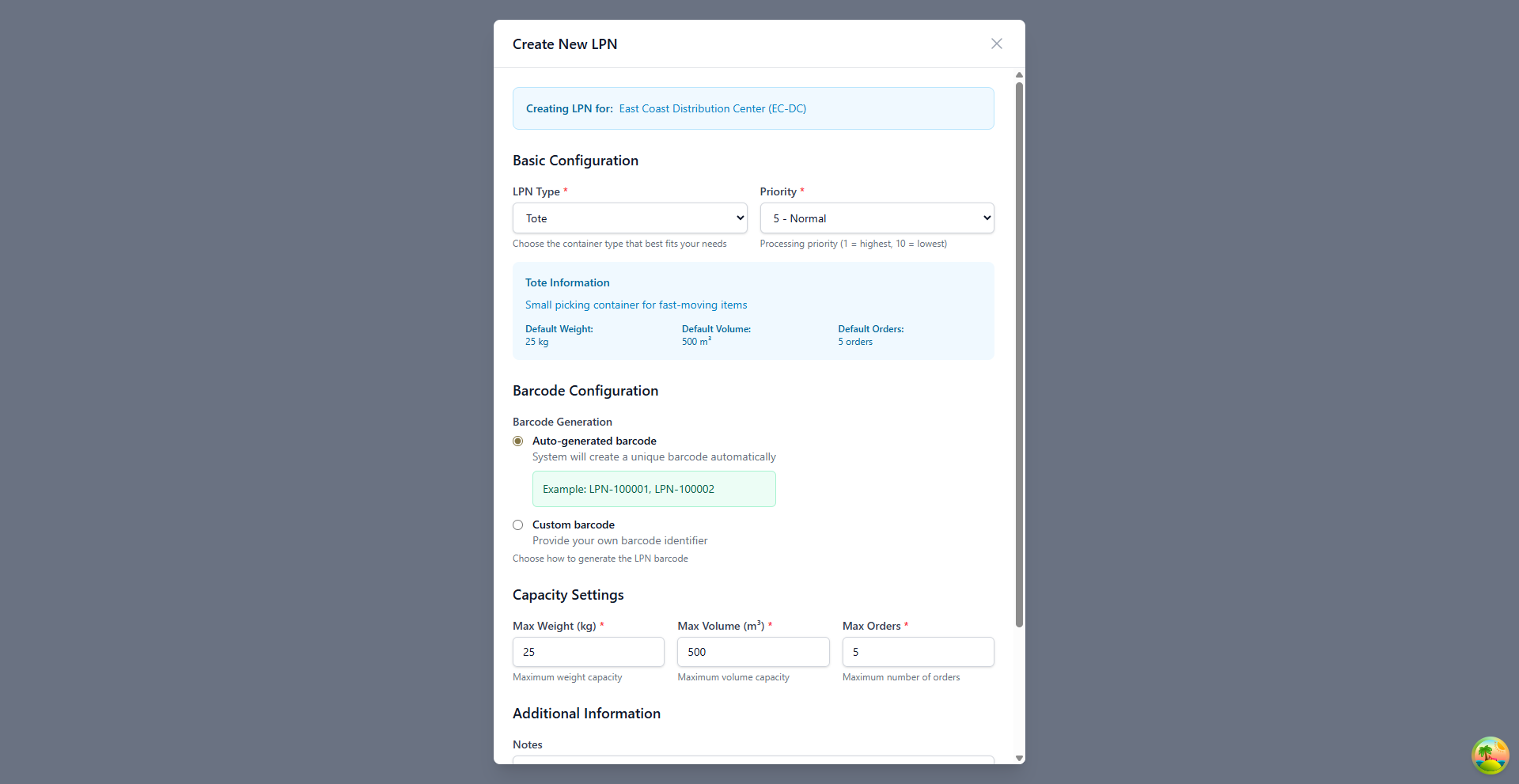

Step 1: Open Create LPN Modal¶

- Click the New LPN button (top right)

- The Create New LPN modal opens

Step 2: Basic Configuration¶

LPN Type *¶

Select the container type that best fits your needs:

- Tote: Small picking container for fast-moving items

-

Default: 25 kg, 500 m³, 5 orders

-

Bin: Medium storage container for organized inventory

-

Default: 50 kg, 1000 m³, 10 orders

-

Box: Standard shipping box for individual orders

-

Default: 20 kg, 300 m³, 1 order

-

Pallet: Large storage unit for bulk inventory

-

Default: 500 kg, 5000 m³, 20 orders

-

Case: Standardized case for product groupings

-

Default: 30 kg, 600 m³, 3 orders

-

Cart: Mobile container for order picking

-

Default: 100 kg, 3000 m³, 8 orders

-

Cage: Secure enclosed container for high-value items

- Default: 200 kg, 2000 m³, 15 orders

Priority *¶

Select processing priority:

- 1 - Highest: Urgent, process immediately

- 2 - High: Priority processing

- 3 - Medium-High: Above normal priority

- 4 - Medium: Standard elevated priority

- 5 - Normal: Default processing (selected by default)

- 6 - Low: Lower priority

- 7 - Lowest: Process when capacity available

Step 3: Barcode Configuration¶

Choose barcode generation method:

Auto-generated barcode (Recommended)¶

- System creates unique barcode automatically

- Format: LPN-100001, LPN-100002, etc.

- No manual input required

- Ensures uniqueness

Custom barcode¶

- Provide your own barcode identifier

- Must be unique across all LPNs

- Use when integrating with external systems

- Supports alphanumeric characters

Step 4: Capacity Settings¶

Configure maximum capacity limits:

Max Weight (kg) * - Maximum weight the container can hold - Pre-filled with type defaults - Adjust based on actual container capacity

Max Volume (m³) * - Maximum volume capacity - Pre-filled with type defaults - Cubic meters or cubic feet based on settings

Max Orders * - Maximum number of orders the LPN can hold - Important for picking operations - Pre-filled with type defaults

Step 5: Additional Information¶

Notes (Optional) - Special handling requirements - Operational notes - Container-specific instructions - Maintenance information

Step 6: Create LPN¶

- Review all configuration

- Click Create LPN

- LPN appears in the list with AVAILABLE status

- Barcode is generated and ready for printing

LPN Details and Contents¶

Viewing LPN Details¶

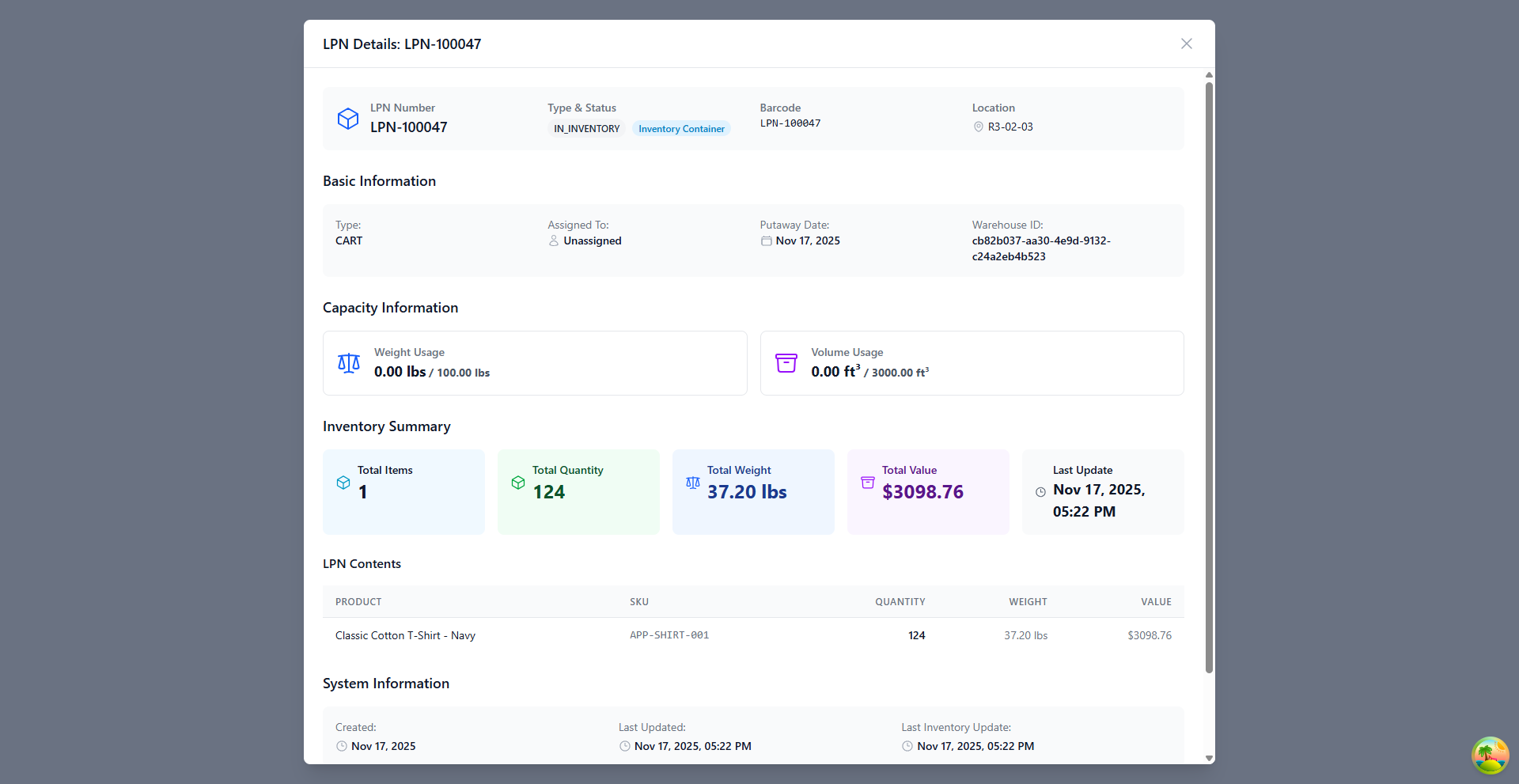

Click on any LPN row to open the LPN Details modal.

Header Information¶

LPN Number: Unique identifier (e.g., LPN-100047)

Type & Status: - Current status badge - Inventory Container indicator (if applicable)

Barcode: Scannable barcode number

Location: Current warehouse location (if assigned)

Basic Information¶

| Field | Description |

|---|---|

| Type | Container type (CART, TOTE, PALLET, etc.) |

| Assigned To | User or process assigned to this LPN |

| Putaway Date | Date LPN was put away to inventory |

| Warehouse ID | Associated warehouse identifier |

Capacity Information¶

Weight Usage - Current weight vs maximum capacity - Shows percentage utilization - Example: 0.00 lbs / 100.00 lbs (0%)

Volume Usage - Current volume vs maximum capacity - Shows percentage utilization - Example: 0.00 ft³ / 3000.00 ft³ (0%)

Inventory Summary¶

Visual cards showing:

- Total Items: Number of different products

- Total Quantity: Total units across all products

- Total Weight: Aggregate weight

- Total Value: Dollar value of contents

- Last Update: Most recent inventory change

LPN Contents Table¶

Detailed product breakdown:

| Column | Description |

|---|---|

| Product | Product name |

| SKU | Product SKU code |

| Quantity | Number of units |

| Weight | Total weight for this product |

| Value | Dollar value (quantity × unit price) |

System Information¶

- Created: LPN creation date

- Last Updated: Most recent LPN modification

- Last Inventory Update: Most recent inventory change

LPN Status Lifecycle¶

Available Statuses¶

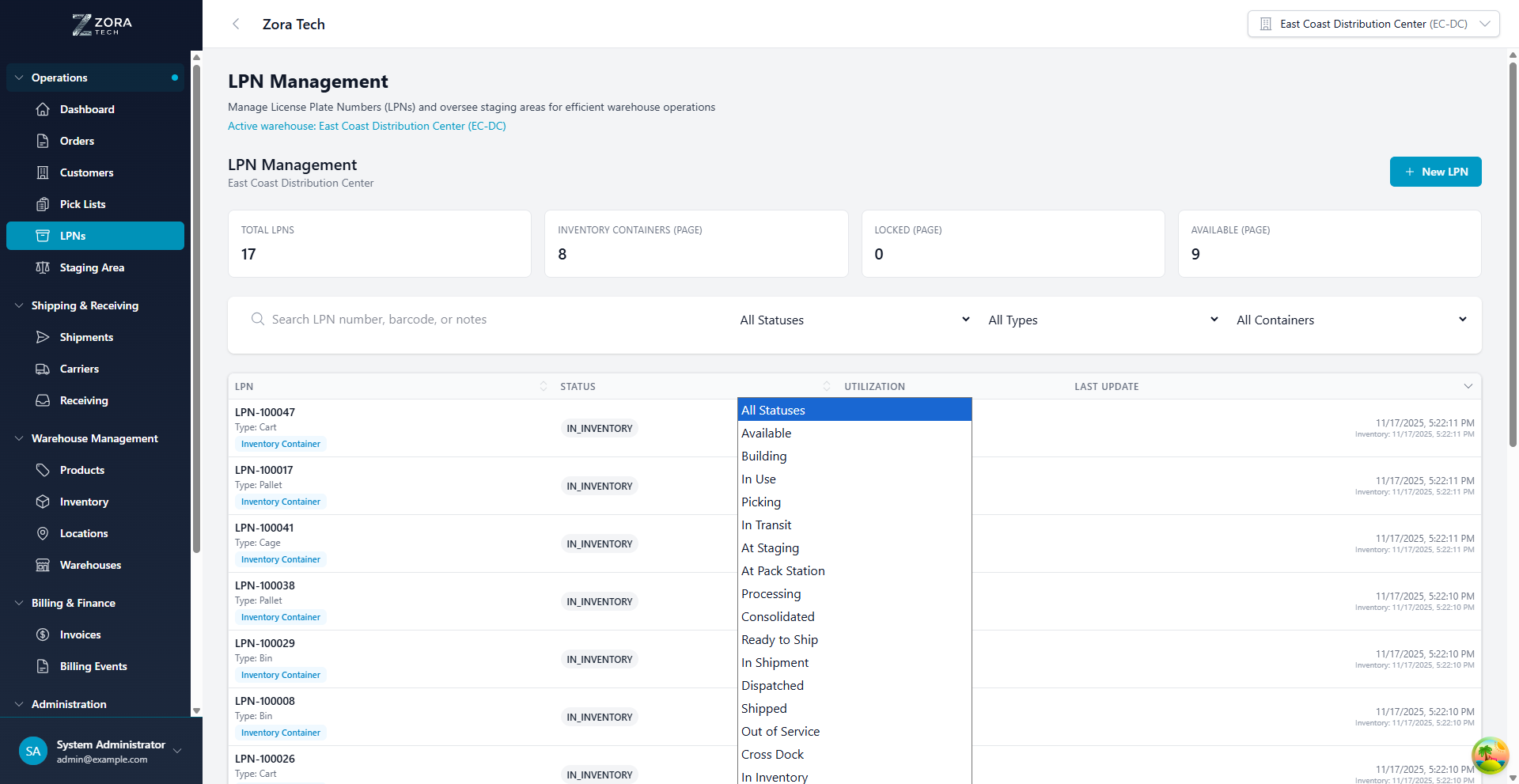

Operational Statuses¶

AVAILABLE - LPN is empty and ready for use - Can be assigned to picking, receiving, or staging - Default status for new operational LPNs

BUILDING - LPN is being filled with inventory or orders - Active in receiving or picking process - Cannot be assigned to other operations

IN_USE - LPN is actively being used in an operation - May be in transit between locations - Locked to current operation

PICKING - LPN is assigned to a pick list - Being filled during order picking - Moves to At Staging when picking complete

AT_STAGING - LPN has been moved to staging area - Awaiting next processing step - Common for orders awaiting packing

AT_PACK_STATION - LPN is at a packing station - Contents being packed for shipment - Moves to Processing when packing starts

PROCESSING - LPN contents are being actively processed - Packing, quality check, or other operations - Cannot be reassigned

CONSOLIDATED - Multiple LPNs consolidated into one - Part of order consolidation workflow - Awaiting final packing

READY_TO_SHIP - LPN contents packed and labeled - Awaiting carrier pickup - Final pre-shipment status

IN_SHIPMENT - LPN included in a shipment - Assigned to specific carrier and tracking number - In transit

DISPATCHED - Shipment has left the warehouse - LPN in transit to destination - Tracking active

SHIPPED - Delivery confirmed - LPN cycle complete - Returns to AVAILABLE if reusable

Inventory Statuses¶

IN_INVENTORY - LPN is an inventory container - Holds inventory in a fixed location - Not moving through operational workflows

INVENTORY_LOCKED - Inventory container with locked status - No changes allowed to contents - Used during cycle counts or quality holds

PUTAWAY_PENDING - LPN received and awaiting putaway - Contents verified but not yet stored - Awaiting location assignment

Special Statuses¶

IN_TRANSIT - LPN moving between warehouse locations - Internal transfer in progress - Not yet at destination

CROSS_DOCK - LPN in cross-docking operation - Received and immediately staged for outbound - Minimizes storage time

OUT_OF_SERVICE - LPN damaged or unavailable - Requires maintenance or repair - Cannot be assigned to operations

Search and Filtering¶

Search Functionality¶

The search bar filters LPNs by: - LPN number (e.g., LPN-100047) - Barcode - Notes or special instructions

Filter Options¶

Status Filter - Filter by any LPN status - See LPN Status Lifecycle for all statuses - Multiple status filtering available

Type Filter - All Types - Tote - Bin - Box - Pallet - Case - Cart - Cage

Container Filter - All Containers: Shows all LPNs - Inventory Containers: Only LPNs designated for inventory storage - Operational LPNs: Only LPNs used in active operations

Clearing Filters¶

- Filters persist across page refreshes

- Change filter selections to update results

- Search and filters work together

LPN Types¶

Tote¶

Use Case: Small picking container for fast-moving items

Default Capacity: - Weight: 25 kg - Volume: 500 m³ - Orders: 5

Best For: - Individual order picking - Small parts storage - Fast-moving SKUs - Returns processing

Bin¶

Use Case: Medium storage container for organized inventory

Default Capacity: - Weight: 50 kg - Volume: 1000 m³ - Orders: 10

Best For: - Inventory storage - Medium-sized products - Multi-SKU storage - Batch picking

Box¶

Use Case: Standard shipping box for individual orders

Default Capacity: - Weight: 20 kg - Volume: 300 m³ - Orders: 1

Best For: - Single order fulfillment - Direct-to-consumer shipping - Small item shipments - Gift packaging

Pallet¶

Use Case: Large storage unit for bulk inventory

Default Capacity: - Weight: 500 kg - Volume: 5000 m³ - Orders: 20

Best For: - Bulk inventory storage - Large product storage - Inbound receiving - Transfer operations

Case¶

Use Case: Standardized case for product groupings

Default Capacity: - Weight: 30 kg - Volume: 600 m³ - Orders: 3

Best For: - Case picking - Product groupings - Wholesale orders - Store replenishment

Cart¶

Use Case: Mobile container for order picking

Default Capacity: - Weight: 100 kg - Volume: 3000 m³ - Orders: 8

Best For: - Multi-order picking - Wave picking - Zone picking - Mobile operations

Cage¶

Use Case: Secure enclosed container for high-value items

Default Capacity: - Weight: 200 kg - Volume: 2000 m³ - Orders: 15

Best For: - High-value inventory - Secure storage - Electronics - Pharmaceuticals

Inventory Containers vs Operational LPNs¶

Inventory Containers¶

Purpose: Long-term inventory storage

Characteristics: - Assigned to specific warehouse locations - Status: IN_INVENTORY or INVENTORY_LOCKED - Not actively moving through workflows - Focus on inventory tracking - Higher capacity (usually Pallets, Bins, Cages)

Usage: - Bulk inventory storage - Slow-moving SKU storage - Reserve inventory - Cycle count units

Operational LPNs¶

Purpose: Active warehouse operations

Characteristics: - Move through picking, packing, staging workflows - Various statuses based on current operation - Return to AVAILABLE when empty - Focus on order fulfillment - Smaller, mobile containers (Totes, Boxes, Carts)

Usage: - Order picking - Packing operations - Staging management - Transfer operations

LPN Movements¶

Overview¶

LPN Movements allow manual relocation of LPN containers throughout your warehouse independently of standard receiving, picking, and shipping workflows. This provides flexibility for warehouse reorganization, replenishment, and inventory management.

When to Use LPN Movement:

- Warehouse reorganization and optimization

- Replenishment (bulk to pick locations)

- Consolidation of partial pallets

- Staging preparation for shipments

- Returns processing (staging back to inventory)

- Error correction (misplaced LPNs)

Movement Types¶

Inventory to Inventory - Move LPN between storage locations - Status remains IN_INVENTORY - Use for reorganization and optimization

Inventory to Staging - Move LPN to shipping staging area - Status changes to STAGED - Prepares items for shipment loading

Staging to Shipment - Load LPN onto outbound shipment - Status changes to SHIPPED - Final step before dispatch

Staging to Inventory - Return LPN from staging to storage - Status returns to IN_INVENTORY - Use for cancelled orders or returns

Mobile-Optimized Workflow¶

LPN Movements are optimized for mobile devices with barcode scanning:

- Scan Source LPN - System shows current location

- Scan Destination - Location, staging area, or shipment

- System Validates - Ensures valid movement

- Confirm Movement - Single tap confirmation

- Physically Move - Relocate LPN to match system

- Complete - Movement recorded with audit trail

Quick Movement Features¶

- Batch Movement: Move multiple LPNs to same destination efficiently

- Recent Destinations: System remembers common movements

- Offline Queue: Movements sync when connection restored

- Haptic Feedback: Physical confirmation of successful scans

- Movement History: Complete audit trail for all LPN movements

System Validations¶

The system prevents invalid movements:

- ✅ Valid source and destination

- ✅ Sufficient capacity at destination (if enforced)

- ✅ LPN not locked by active process

- ✅ Shipment not yet dispatched (for shipment loads)

- ❌ Cannot unload from dispatched shipment

- ❌ Cannot move during active receiving/picking

Learn More¶

For complete LPN Movement workflow, best practices, and scenarios:

Covers: - Detailed step-by-step workflows - Common movement scenarios - Mobile scanning procedures - Troubleshooting and validation - Integration with other warehouse operations

Best Practices¶

LPN Creation¶

- Standardize Container Types

- Use consistent types across similar operations

- Match container type to warehouse processes

-

Document type usage in SOPs

-

Set Realistic Capacities

- Adjust defaults based on actual container sizes

- Account for product characteristics

-

Consider operational constraints

-

Use Auto-Generated Barcodes

- Ensures uniqueness

- Simplifies LPN creation

- Reduces manual errors

-

Use custom barcodes only for integration needs

-

Appropriate Priority Levels

- Reserve priority 1-2 for urgent operations

- Use priority 5 (Normal) for standard operations

- Lower priorities for slow-moving operations

Operational Best Practices¶

- Regular Status Updates

- Scan LPNs at each workflow step

- Update status immediately after changes

-

Resolve stuck LPNs promptly

-

Maintain LPN Pool

- Keep adequate AVAILABLE LPNs for each type

- Monitor LPN utilization rates

-

Create additional LPNs during peak periods

-

Inventory Container Management

- Assign to fixed locations

- Perform regular cycle counts

- Use INVENTORY_LOCKED during counts

-

Document putaway dates

-

Clean Up Completed LPNs

- Return operational LPNs to AVAILABLE promptly

- Clear contents when operations complete

- Inspect containers for damage

- Mark damaged containers OUT_OF_SERVICE

Data Integrity¶

- Accurate Capacity Tracking

- Update weight and volume after changes

- Verify capacity limits not exceeded

-

Investigate utilization anomalies

-

Location Accuracy

- Update location after every move

- Scan LPNs at destination

-

Reconcile location discrepancies

-

Notes and Documentation

- Add notes for special handling

- Document operational issues

- Track damage or maintenance needs

Troubleshooting¶

Common Issues¶

LPN Not Appearing in List¶

Problem: Created LPN doesn't show in the table

Solutions: 1. Check status filter - LPN may be filtered out 2. Verify correct warehouse selected 3. Clear search filters 4. Refresh the page 5. Check if LPN was created successfully

Cannot Create New LPN¶

Problem: Create LPN button disabled or creation fails

Solutions: 1. Verify warehouse is selected 2. Check user permissions for LPN creation 3. Ensure all required fields are filled 4. Check for duplicate barcode (if using custom) 5. Contact system administrator if issue persists

LPN Stuck in Status¶

Problem: LPN not progressing through workflow statuses

Solutions: 1. Check associated process (pick list, shipment, etc.) 2. Verify scan at workflow checkpoints 3. Complete or cancel associated operation 4. Contact supervisor for manual status override 5. Check system logs for errors

Capacity Exceeded Errors¶

Problem: Cannot add items to LPN - capacity exceeded

Solutions: 1. Check current weight and volume utilization 2. Verify max capacity settings are correct 3. Use larger container type if needed 4. Split contents across multiple LPNs 5. Remove some items to stay within limits

LPN Not Scanning¶

Problem: Barcode scanner doesn't recognize LPN

Solutions: 1. Verify scanner is configured for LPN barcodes 2. Clean barcode label if dirty or damaged 3. Manually enter LPN number 4. Reprint barcode label 5. Check scanner battery and connection

Inventory Discrepancies¶

Problem: LPN contents don't match system records

Solutions: 1. Perform physical count of LPN contents 2. Compare against LPN Contents table 3. Check recent inventory transactions 4. Look for duplicate LPNs with similar numbers 5. Submit discrepancy report for investigation

Error Messages¶

| Error | Cause | Resolution |

|---|---|---|

| "LPN number already exists" | Duplicate custom barcode | Use different barcode or auto-generate |

| "Warehouse required" | No warehouse selected | Select warehouse from header dropdown |

| "Invalid capacity values" | Negative or zero capacity | Enter positive capacity values |

| "Maximum capacity exceeded" | Adding too much to LPN | Use larger LPN or split across multiple |

| "LPN is locked" | Inventory locked status | Complete cycle count or unlock inventory |

| "Cannot delete LPN with contents" | LPN has inventory | Clear contents first, then delete |

Getting Help¶

If you encounter issues not covered here:

- Check LPN Details: Review all fields for accuracy

- Review Workflow Status: Ensure LPN is in correct workflow step

- Contact Supervisor: For operational workflow issues

- System Administrator: For technical or permission issues

- Support Team: Provide LPN number and error details

Related Topics¶

- Receiving Operations - LPN usage in receiving

- Order Processing - LPN usage in fulfillment

- Inventory Management - Inventory container management

- Staging Area - LPN staging operations

Support¶

For LPN-related questions or issues:

- Email: support@zoratech.io

- Documentation: Troubleshooting Guide

- FAQ: Frequently Asked Questions