Inventory Management User Guide¶

Table of Contents¶

- Overview

- Accessing Inventory Management

- Adding New Inventory

- Viewing and Managing Inventory

- Advanced Inventory Features

- Understanding Inventory Information

- Warehouse Context Management

- Inventory Workflows

- Best Practices

- Troubleshooting

Overview¶

The Inventory Management system in Zora Tech's Logistics Platform provides comprehensive tracking of all products across your warehouse facilities. This advanced system offers real-time visibility into stock levels, locations, and product movements with sophisticated tracking capabilities.

Key Features¶

- Real-time inventory tracking: Monitor current stock levels and availability across all locations

- Advanced product tracking: Support for lot/serial number tracking for full traceability

- Multi-location support: Track products across different warehouse locations with hierarchical organization

- Smart filtering: Find products by status (low stock, expiring, etc.) with intelligent search

- Warehouse context switching: Seamlessly view and manage inventory for specific warehouses

- Comprehensive product details: Access complete product information, tracking history, and transaction records

- Expiration management: Monitor expiration dates with automated alerts for expiring products

- Cost tracking: Track unit costs and calculate total inventory values

- Transaction history: Complete audit trail of all inventory movements and changes

Accessing Inventory Management¶

Prerequisites¶

- Valid login credentials to the Zora Tech Logistics Platform

- Appropriate permissions to access inventory data

- At least one active warehouse configured in the system

- Products and locations must be configured before adding inventory

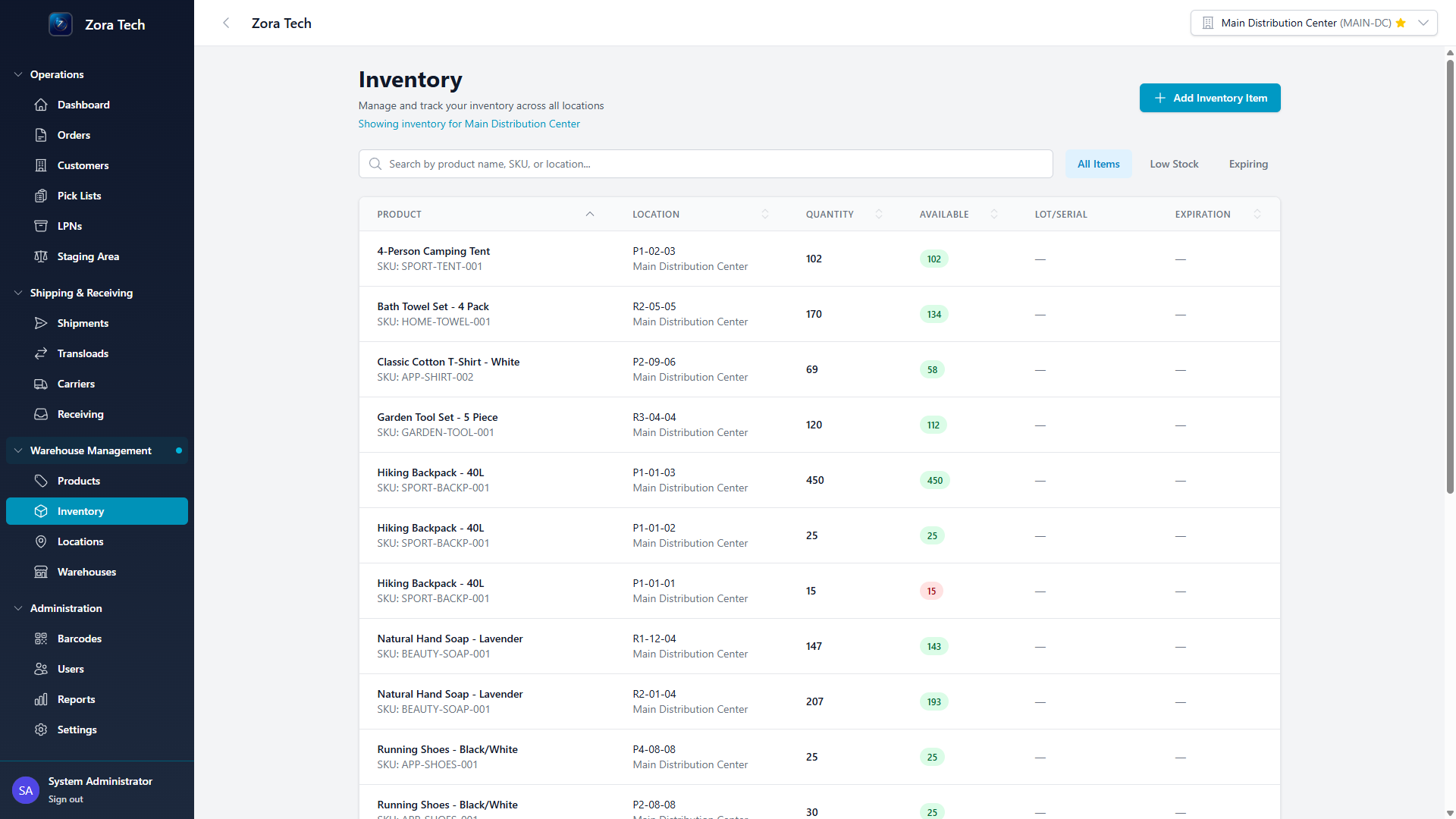

Step 1: Navigate to Inventory¶

- From the main dashboard, locate the "Inventory Management" section in the left sidebar

- Click on "Inventory"

- The inventory management page displays:

- Page header with warehouse context and inventory summary

- Add Inventory button for adding new inventory items

- Advanced search and filter tools for finding specific products

- Smart status filters (All Items, Low Stock, Expiring)

- Comprehensive inventory table with sortable columns

- Real-time data showing quantities, locations, and status information

Page Layout Elements¶

- Warehouse Context Indicator: Shows current warehouse (e.g., "Showing inventory for Demo Warehouse Facility")

- URL Parameter Filters: Display active filters from navigation (Product ID, Location ID, etc.)

- Search Bar: Advanced search by product name, SKU, or location code

- Status Filter Buttons: Quick access to All Items, Low Stock, and Expiring inventory

- Inventory Table: Comprehensive view with product, location, quantity, and tracking information

Adding New Inventory¶

Step 1: Access Add Inventory Modal¶

- From the inventory management page, click the "Add Inventory Item" button in the top-right corner

- The Add Inventory Modal opens with multiple organized sections for comprehensive inventory entry

Step 2: Complete Inventory Information¶

The Add Inventory Modal is organized into six main sections:

Warehouse Context (Auto-displayed)¶

- Shows the current warehouse you're adding inventory to

- Displays warehouse name and code for confirmation

- Cannot be changed from this modal (switch warehouse context from the main page if needed)

Item Selection¶

- Product Selection:

- Use the advanced Product Selector to search by name, SKU, or barcode

- Type to search and select from available products

- Product information automatically displays once selected

- Location Selection:

- Choose from available locations in the current warehouse

- Locations are filtered by warehouse context

- Shows location codes in hierarchical format (Aisle-Shelf-Bin)

Quantity and Cost¶

- Quantity Entry:

- Enter the quantity being added to inventory

- For serial-tracked products, quantity is locked to 1

- System validates positive numbers only

- Unit Cost (Optional):

- Enter the cost per unit for inventory valuation

- System automatically calculates total value

- Helps with inventory cost tracking and reporting

Tracking Information (Product-dependent)¶

This section appears only for products with tracking requirements: 1. Lot Number (for lot-tracked products): - Required field for products with lot tracking enabled - Enter manufacturing lot or batch number - Used for traceability and recall management 2. Serial Number (for serial-tracked products): - Required field for products with serial tracking enabled - Enter unique serial number for the item - Quantity must be 1 for serial-tracked items

Date Information¶

- Received Date:

- Required field, defaults to today's date

- Cannot be set to future dates

- Represents when inventory was physically received

- Expiration Date (Optional):

- Set expiration date for products with shelf life

- Must be after the received date

- Used for expiration monitoring and alerts

Additional Information¶

- Notes (Optional):

- Free-text field for additional information

- Record supplier information, condition notes, etc.

- Helps with inventory documentation and history

Step 3: Review and Submit¶

- Validation: System automatically validates all required fields and business rules

- Review: Check all information before submitting

- Submit: Click "Add Inventory Item" to create the inventory record

- Confirmation: System confirms successful creation and updates inventory list

Smart Features in Add Inventory¶

Product Information Display¶

When a product is selected, the modal automatically shows: - Unit of measure - Tracking requirements (lot/serial) - Reorder point information - Product specifications

Automatic Calculations¶

- Total inventory value calculation (quantity × unit cost)

- Real-time validation of dates and quantities

- Business rule enforcement (serial tracking = quantity 1)

Warehouse-Filtered Locations¶

- Only shows locations belonging to the selected warehouse

- Prevents cross-warehouse inventory errors

- Maintains data integrity

Viewing and Managing Inventory¶

Inventory Table Features¶

The inventory management table provides comprehensive information at a glance:

Table Columns¶

- Product: Shows product name and SKU

- Location: Displays location code and warehouse name

- Quantity: Total quantity at this location

- Available: Available quantity with smart status badges

- Green badge for normal stock levels

- Red badge for low stock (below reorder point)

- Lot/Serial: Shows lot numbers and serial numbers when applicable

- Expiration: Displays expiration dates with status indicators

- Red "EXPIRED" badge for expired items

- Yellow "EXPIRING_SOON" badge for items expiring within 30 days

Interactive Features¶

- Sortable Columns: Click column headers to sort data

- Row Selection: Click any row to view detailed information

- Status Indicators: Color-coded badges for quick status identification

- Mobile Optimization: Responsive design with priority-based column display

Advanced Search and Filtering¶

Search Functionality¶

- Multi-field Search: Search across product names, SKUs, and location codes

- Real-time Results: Results update as you type

- Case-insensitive: Search works regardless of capitalization

Status-based Filters¶

- All Items: Shows complete inventory across all locations

- Low Stock: Displays items below their reorder point

- Expiring: Shows items expiring within 30 days

URL Parameter Filtering¶

The system supports advanced filtering through URL parameters: - Product ID Filter: Shows inventory for a specific product - Location ID Filter: Shows inventory at a specific location

- Warehouse ID Filter: Shows inventory in a specific warehouse - Clear Filters: One-click removal of all active filters

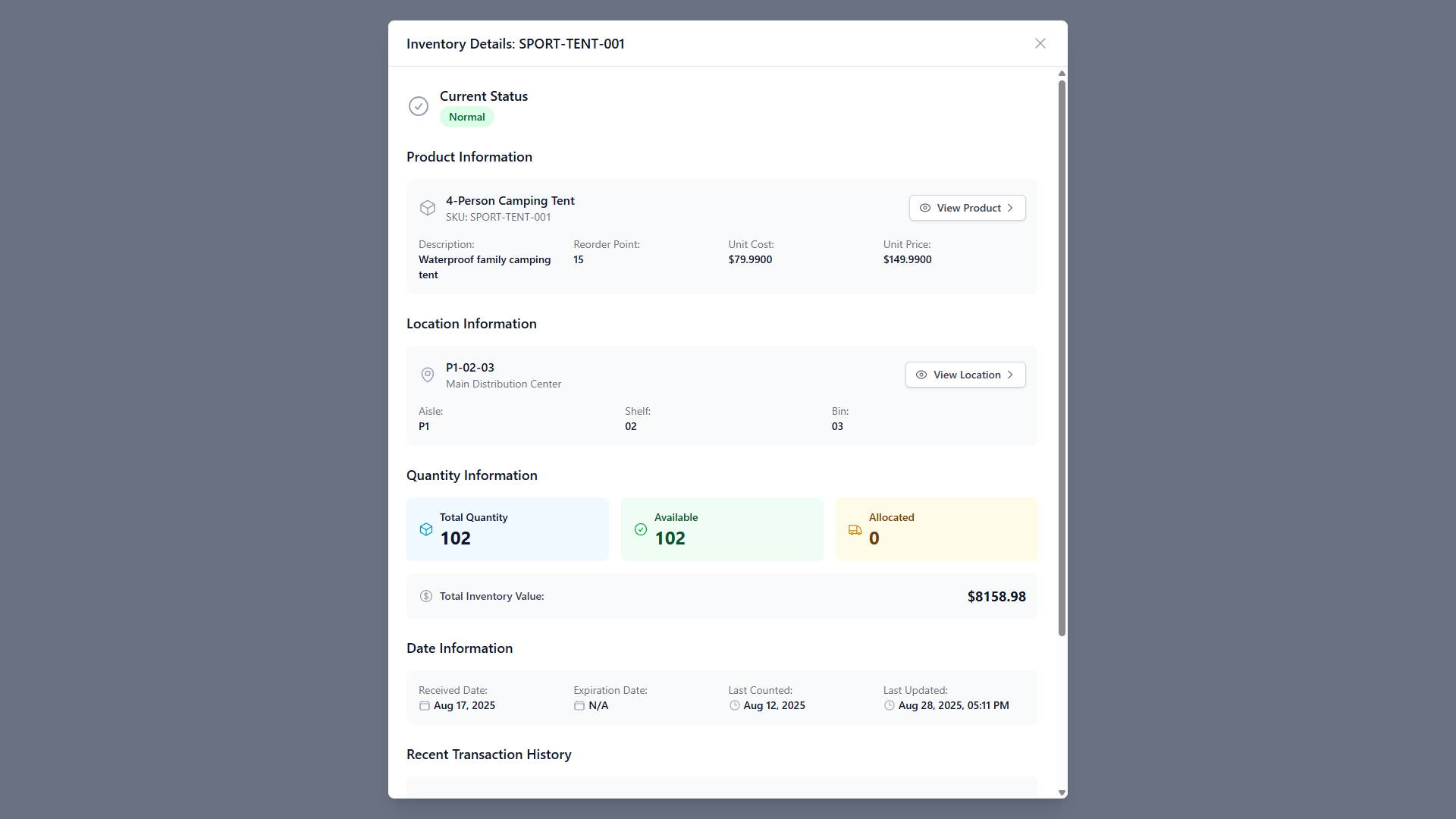

Step 1: Access Inventory Details¶

To view comprehensive information about any inventory item:

- Click on any product row in the inventory table

- The Inventory Detail Modal opens with extensive information

Step 2: Review Comprehensive Inventory Information¶

The inventory details modal provides complete information organized into eight distinct sections:

1. Status Header¶

- Current Status Badge: Visual indicator showing inventory condition

- Normal: Green badge for healthy inventory levels

- Low Stock: Orange badge when below reorder point

- Expiring Soon: Yellow badge for items expiring within 30 days

- Expired: Red badge for items past expiration date

2. Product Information¶

- Product Name and SKU: Complete product identification

- Description: Detailed product description and specifications

- Reorder Point: Minimum stock level before reordering

- Unit Cost and Price: Product pricing information

- Tracking Requirements: Lot and/or serial tracking indicators

- View Product Button: Direct navigation to product details page

3. Location Information¶

- Location Code: Specific warehouse location (Aisle-Shelf-Bin)

- Warehouse Name: Warehouse where inventory is stored

- Location Hierarchy: Complete location path structure

- View Location Button: Direct navigation to location details

4. Quantity Information (Visual Cards)¶

- Total Quantity: Complete inventory count at this location

- Available Quantity: Stock available for new orders

- Allocated Quantity: Stock reserved for existing orders

- Total Inventory Value: Calculated total value (quantity × cost)

5. Tracking Details (When Applicable)¶

- Lot Number: Manufacturing lot or batch number

- Serial Number: Unique item serial number

- Tracking Status: Visual indicators for lot/serial tracking

6. Date Information¶

- Received Date: When inventory was originally received

- Expiration Date: Product expiration date (color-coded by status)

- Last Counted Date: Most recent physical count

- Last Updated: Most recent system modification

7. Recent Transaction History¶

- Transaction List: Recent inventory movements and changes

- Transaction Types: INBOUND, OUTBOUND, and adjustment transactions

- Transaction Details: Quantity, reason, and timestamp

- Color Coding: Green for inbound, red for outbound, blue for adjustments

8. Navigation Actions¶

- View Product: Navigate to complete product information

- View Location: Navigate to location details and other inventory

- Close Modal: Return to inventory list

Advanced Inventory Features¶

Lot and Serial Number Tracking¶

The platform provides comprehensive traceability through advanced tracking capabilities:

Lot Tracking¶

- Purpose: Track manufacturing batches for quality control and recalls

- Implementation: Multiple items can share the same lot number

- Requirements: Required for products marked as lot-tracked

- Use Cases: Food products, pharmaceuticals, chemicals

- Recall Management: Quickly identify and isolate affected inventory

Serial Number Tracking¶

- Purpose: Track individual items with unique identifiers

- Implementation: Each item has a unique serial number

- Quantity Restriction: Serial-tracked items must have quantity = 1

- Use Cases: Electronics, equipment, high-value items

- Warranty Tracking: Individual item service and warranty history

Expiration Date Management¶

Expiration Monitoring¶

- Automatic Alerts: System identifies items expiring within 30 days

- Status Badges: Visual indicators for expiration status

- Expiring Soon: Yellow badge for items within 30 days of expiration

- Expired: Red badge for items past expiration date

- FIFO Support: First-In-First-Out rotation management

Expiration Workflows¶

- Expiring Filter: Quick access to items requiring attention

- Date Validation: System prevents setting past dates or invalid sequences

- Reporting: Track expiration trends and waste reduction

Cost Tracking and Valuation¶

Unit Cost Management¶

- Optional Entry: Unit costs can be recorded for valuation purposes

- Total Value Calculation: Automatic calculation of inventory value

- Cost Tracking: Historical cost information for analysis

- Valuation Methods: Support for various costing approaches

Financial Integration¶

- Inventory Valuation: Real-time inventory asset values

- Cost Analysis: Track cost trends and variances

- Reporting: Financial reporting and cost accounting support

Transaction History and Audit Trail¶

Complete Transaction Tracking¶

- All Movements: Track every inventory change and movement

- Transaction Types: INBOUND, OUTBOUND, adjustments, and transfers

- Timestamps: Precise date and time recording

- User Attribution: Track who performed each transaction

Audit Capabilities¶

- Full Traceability: Complete chain of custody tracking

- Compliance Support: Meet regulatory requirements

- Historical Analysis: Analyze patterns and trends

- Error Investigation: Research discrepancies and issues

Understanding Inventory Information¶

Advanced Quantity Management¶

Quantity Types¶

Total Quantity: The complete count of this product at this location - Represents actual physical inventory on hand - Includes both available and allocated stock - Updates in real-time with all transactions

Available Quantity: Stock ready for new orders and operations - Not reserved for existing orders or allocations - Available for immediate picking and shipping - Reduces when orders are allocated, increases when orders complete

Allocated Quantity: Stock reserved for pending orders - Currently assigned to orders awaiting fulfillment - Protected from other allocation requests - Returns to available when orders are cancelled or completed

Smart Status Indicators¶

The system provides intelligent status monitoring:

Normal Status (Green Badge): - Available quantity above reorder point - No expiration concerns - Ready for operations

Low Stock (Orange Badge): - Available quantity at or below reorder point - Requires attention for replenishment - May impact order fulfillment

Expiring Soon (Yellow Badge): - Items expiring within 30 days - Requires priority usage or disposition - FIFO rotation recommended

Expired (Red Badge): - Items past expiration date - Requires immediate attention - May need disposal or return

Multi-Location Inventory Management¶

Location Hierarchy¶

Products can be stored across multiple locations with hierarchical organization: - Warehouse Level: Top-level organization by facility - Aisle Level: Logical groupings within warehouses - Shelf Level: Specific storage areas within aisles - Bin Level: Precise storage locations on shelves

Location-Specific Tracking¶

- Individual Records: Each location maintains separate inventory records

- Consolidated Views: System provides warehouse and company-wide totals

- Movement History: Track inventory transfers between locations

- Location Optimization: Analyze location efficiency and utilization

Warehouse Context Management¶

Understanding Warehouse Context¶

The inventory management system operates within a warehouse context that filters all operations and views:

Warehouse Context Indicator¶

- Location: Top of the inventory page

- Display: Shows current warehouse (e.g., "Showing inventory for Demo Warehouse Facility")

- Scope: All inventory operations are filtered by this context

- Switching: Change context from the warehouse selector in the navigation

Context-Filtered Operations¶

Inventory Viewing: - Only shows inventory for the selected warehouse - Filters all search and status operations - Maintains context across page refreshes

Adding Inventory: - New inventory automatically assigned to current warehouse context - Location selection filtered to current warehouse only - Prevents cross-warehouse errors

Navigation Integration: - Breadcrumbs and navigation maintain warehouse context - Deep links preserve warehouse selection - URL parameters support warehouse filtering

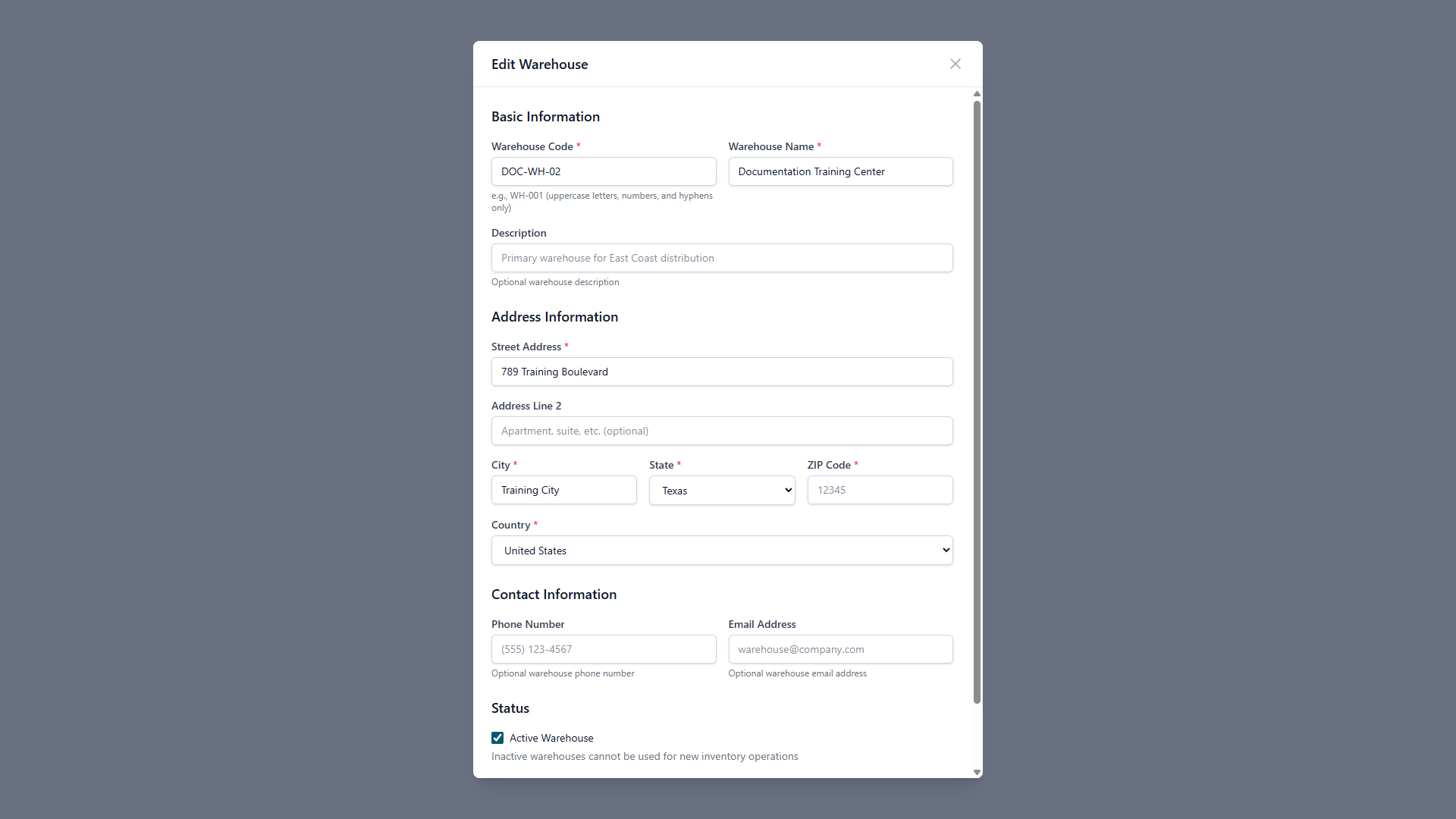

Warehouse Status and Operations Control¶

Active vs. Inactive Warehouses¶

Warehouses can be enabled or disabled to control operational access:

Managing Warehouse Status: 1. Navigate to Warehouse Management → Warehouses 2. Click the "Edit" button next to any warehouse 3. In the edit form, locate the "Active Warehouse" checkbox 4. Checked: Warehouse is active and operational 5. Unchecked: Warehouse is disabled (data preserved but not operational)

Impact of Warehouse Status on Inventory¶

Active Warehouses: - Full inventory operations available - Can add, modify, and track inventory - Supports receiving, picking, and shipping operations - Complete reporting and analytics access

Disabled Warehouses: - Inventory viewing remains available - Cannot add new inventory or modify existing - Historical data and reporting preserved - Operations suspended until re-enabled

Best Practices for Warehouse Management¶

- Temporary Closure: Disable warehouses during maintenance or restructuring

- Seasonal Operations: Disable seasonal warehouses during off-periods

- Data Integrity: All historical data preserved when disabled

- Communication: Notify team members before changing warehouse status

- Context Switching: Train users on warehouse context selection

- Access Control: Ensure appropriate warehouse permissions for users

Inventory Workflows¶

Standard Inventory Addition Workflow¶

Preparation Phase¶

- Verify Prerequisites:

- Ensure warehouse context is correct

- Confirm products are configured in system

- Verify locations exist and are active

-

Check user permissions for inventory addition

-

Gather Information:

- Product identification (name, SKU, or barcode)

- Quantity being added

- Location for storage

- Unit cost (if tracking financial values)

- Lot/serial information (if required)

- Received and expiration dates

Addition Process¶

- Access Add Inventory Modal: Click "Add Inventory Item" button

- Product Selection: Use product selector to find and select item

- Location Assignment: Choose appropriate storage location

- Quantity and Cost: Enter quantities and optional cost information

- Tracking Data: Complete lot/serial information if required

- Date Information: Set received date and optional expiration

- Documentation: Add notes for additional context

- Validation and Submit: Review all information and create record

Post-Addition Activities¶

- Verification: Confirm inventory appears in system

- Physical Organization: Ensure items are properly stored at location

- Documentation: Update any external tracking systems

- Team Communication: Notify relevant team members if needed

Inventory Research and Analysis Workflow¶

Locating Specific Inventory¶

- Search Methods:

- Use search bar for product names, SKUs, or locations

- Apply status filters (All, Low Stock, Expiring)

-

Use URL parameters for specific product/location filtering

-

Analysis Process:

- Click inventory row to open detailed view

- Review status indicators and alerts

- Examine transaction history

- Check tracking information

- Evaluate quantity levels against reorder points

Status Investigation¶

- Low Stock Items:

- Use "Low Stock" filter to identify items needing replenishment

- Review reorder points and available quantities

- Check recent transaction history for consumption patterns

-

Coordinate with purchasing for replenishment

-

Expiring Items:

- Use "Expiring" filter to identify items requiring attention

- Prioritize items closest to expiration

- Consider FIFO rotation strategies

- Plan disposition for expired items

Cross-System Navigation Workflows¶

Product-Centric Research¶

- From Inventory to Product: Click "View Product" in inventory details modal

- Product Analysis: Review complete product information and specifications

- System-Wide Inventory: See all locations where product is stored

- Related Information: Access product history, specifications, and settings

Location-Centric Analysis¶

- From Inventory to Location: Click "View Location" in inventory details modal

- Location Overview: See all products stored at that location

- Capacity Analysis: Evaluate location utilization and capacity

- Movement History: Review location-based transaction history

Best Practices¶

Inventory Data Management¶

Data Entry Best Practices¶

Consistent Information: - Use standardized lot numbering conventions across your organization - Maintain consistent serial number formats for trackable items - Enter complete product information including unit costs when available - Use descriptive notes to provide context for future reference

Date Management: - Always enter received dates accurately for inventory aging analysis - Set expiration dates for perishable items to enable proper rotation - Use consistent date formats across all entries - Validate date sequences (expiration after received date)

Location Assignment: - Follow logical location assignment patterns (faster moving items in accessible areas) - Maintain location cleanliness and organization standards - Use location hierarchy effectively (warehouse → aisle → shelf → bin) - Consider product compatibility when assigning adjacent locations

Operational Workflows¶

Daily Operations¶

Morning Inventory Review: - Check "Low Stock" filter for items requiring replenishment - Review "Expiring" filter for items needing immediate attention - Monitor available vs. allocated quantities for order fulfillment capacity - Verify warehouse context is correctly set for your operations

Ongoing Monitoring: - Use status badges to quickly identify inventory requiring attention - Leverage real-time search capabilities for quick product location - Maintain physical organization matching system locations - Update inventory movements promptly to maintain accuracy

Weekly Analysis¶

Inventory Health Checks: - Review transaction history for unusual patterns or discrepancies - Analyze slow-moving inventory for disposition decisions - Evaluate location utilization and capacity planning - Assess reorder points against actual consumption patterns

Data Quality Reviews: - Verify lot/serial tracking information accuracy - Check expiration date accuracy and update as needed - Review and clean up obsolete or duplicate inventory records - Validate location assignments and physical organization

Multi-Warehouse Operations¶

Warehouse Context Management¶

Context Switching: - Always verify warehouse context before performing operations - Train team members on proper warehouse selection procedures - Use context indicators to avoid cross-warehouse errors - Maintain warehouse-specific operational procedures

Cross-Warehouse Coordination: - Understand inventory visibility across multiple warehouses - Coordinate inter-warehouse transfers through proper channels - Maintain consistent product and location coding across facilities - Use warehouse-specific reporting for operational decisions

Access Control and Permissions¶

User Training: - Ensure users understand warehouse context implications - Train on proper use of search and filtering capabilities - Emphasize importance of accurate data entry - Provide guidance on status interpretation and action requirements

Technology Utilization¶

Search and Navigation Optimization¶

Efficient Searching: - Use specific search terms for faster results (SKU, product name, location code) - Leverage status filters to focus on items requiring attention - Combine search terms with filters for precise results - Bookmark frequently accessed products or locations in browser

System Integration: - Use cross-navigation features to research related information - Leverage URL parameter filtering for specific analysis needs - Take advantage of real-time data updates for current information - Use transaction history for troubleshooting and analysis

Mobile and Accessibility¶

Mobile Operations: - Use responsive design features for mobile inventory management - Take advantage of touch-optimized interfaces for warehouse floor operations - Leverage mobile search capabilities for quick lookups - Use mobile-friendly status indicators for quick status assessment

Troubleshooting¶

Common Issues and Solutions¶

Inventory Data Issues¶

Issue: Inventory quantities seem incorrect or inconsistent - Immediate Check: Review recent transaction history in inventory details modal - Verification Steps: - Check allocated quantities against open orders - Review INBOUND/OUTBOUND transactions for recent changes - Verify warehouse context is correct for your expectations - Advanced Troubleshooting: Compare available + allocated = total quantity calculation - Escalation: Contact administrator if discrepancies persist after verification

Issue: Cannot find specific products in inventory - Search Strategy: - Try broader search terms or clear all active filters - Use SKU search instead of product name for precise results - Check if you're in the correct warehouse context - Filter Review: Clear URL parameter filters (Product ID, Location ID, Warehouse ID) - Alternative Approach: Navigate to Products page and use "View Inventory" from there - Verification: Confirm product exists in system and has inventory records

Issue: Add Inventory Modal shows no available locations - Warehouse Check: Verify you're in the correct warehouse context - Location Status: Confirm locations exist and are active in the selected warehouse - Permission Verification: Ensure you have access to create inventory in current warehouse - System Check: Contact administrator if locations should exist but aren't visible

Performance and Display Issues¶

Issue: Inventory details modal not displaying or loading slowly - Immediate Solution: Refresh the page and try again - Network Check: Verify stable internet connection and network performance - Browser Check: Try accessing from a different browser or clear browser cache - Data Volume: Large transaction histories may take time to load - Alternative: Try accessing inventory details for different items to isolate the issue

Issue: Status badges or indicators not displaying correctly - Cache Clear: Clear browser cache and refresh the page - Data Refresh: Close and reopen inventory details modal - Timing: Allow time for real-time updates to propagate - Browser Compatibility: Ensure you're using a supported browser version

Issue: Warehouse context seems stuck or incorrect - Context Reset: Use warehouse selector in navigation to explicitly change context - Browser Refresh: Refresh the page to reload warehouse context - Local Storage: Clear browser local storage if context persists incorrectly - User Default: Contact administrator to verify your default warehouse settings

Functional Operation Issues¶

Issue: Cannot add inventory (modal not submitting) - Validation Check: Review all required fields and error messages - Product Requirements: Verify lot/serial number requirements for selected product - Date Validation: Ensure received date is not in future, expiration after received date - Permission Check: Verify you have inventory creation permissions - Network Stability: Check network connection during submission

Issue: Search and filtering not working as expected - Filter Combination: Try using filters individually rather than combined - Search Terms: Use more specific or alternative search terms - Case Sensitivity: Search is case-insensitive, but try exact matches - Special Characters: Avoid special characters that might interfere with search - Reset Approach: Clear all filters and search terms, then rebuild query

Issue: Transaction history not loading or incomplete - Wait Time: Allow additional time for transaction data to load - Network Check: Verify stable network connection - Data Scope: Transaction history shows most recent 10 transactions by default - Alternative Access: Try viewing transaction history for different products - System Status: Check if inventory transaction services are operational

Access and Permission Issues¶

Issue: Warehouse appears inactive or inaccessible - Status Check: Verify warehouse is enabled in warehouse management settings - Permission Verification: Confirm you have access permissions for the warehouse - User Role: Check your user role includes inventory access for this warehouse - Administrator Contact: Contact administrator to enable warehouse or adjust permissions

Issue: Cannot switch between warehouses - Navigation Check: Ensure warehouse selector is accessible in your user interface - Permission Review: Verify you have access to multiple warehouses - Role Verification: Confirm your user role supports multi-warehouse access - Cache Clear: Clear browser cache if warehouse list not updating

Performance Optimization¶

System Performance Tips¶

- Regular Cache Clear: Clear browser cache weekly for optimal performance

- Network Stability: Use stable network connection for best experience

- Browser Updates: Keep browser updated to latest version

- Concurrent Users: Be aware that system performance may vary with user load

Data Management for Performance¶

- Specific Searches: Use specific search terms rather than broad queries

- Filter Usage: Apply filters to reduce data volume for faster loading

- Batch Operations: Group similar inventory operations together

- Regular Maintenance: Keep inventory data clean and up-to-date

Getting Additional Help¶

Self-Service Resources¶

- System Status: Check platform status dashboard if available

- Browser Diagnostics: Try different browsers or incognito mode

- Network Testing: Test network connectivity and speed

- Documentation Review: Consult related user guides (Products, Locations, Warehouses)

Escalation Process¶

- Screenshot Documentation: Capture screenshots of issues for support requests

- Error Information: Note exact error messages and browser console information

- Reproduction Steps: Document steps to reproduce the issue

- Contact Administrator: Report persistent issues with detailed information

- Support Ticket: Follow organizational procedures for technical support requests

Integration Notes¶

Cross-System Data Flow¶

Real-time Updates¶

Inventory levels update immediately when: - Products are received into inventory through receiving workflows - Items are allocated to orders during order processing - Products are shipped or consumed through fulfillment workflows - Manual adjustments are made through inventory management - Inter-warehouse transfers are completed

Multi-Module Integration¶

Inventory data integrates seamlessly with: - Product Management: Product specifications, tracking requirements, and reorder points - Location Management: Hierarchical location structure and capacity management - Order Management: Automatic allocation and availability checking - Receiving Workflows: Direct inventory updates from inbound shipments

- Shipping Operations: Real-time quantity adjustments during fulfillment - Reporting Systems: Historical and current inventory analytics and valuation

User Permissions and Access Control¶

Role-Based Access¶

Inventory Viewer: Can view inventory information and details Inventory Manager: Can view and add inventory items Warehouse Manager: Full inventory operations within assigned warehouses System Administrator: Complete inventory management across all warehouses

Warehouse-Specific Permissions¶

- Users can be granted access to specific warehouses only

- Warehouse context automatically filters based on user permissions

- Multi-warehouse access requires appropriate role assignments

- Administrative functions require elevated permissions

Last Updated: August 2025

Version: 2.0

For additional assistance, advanced features, or integration support, please contact your system administrator or refer to the complete Zora Tech Logistics Platform documentation.

Integration Notes¶

Data Flow¶

Real-time Updates: Inventory levels update immediately when: - Products are received into inventory - Items are allocated to orders - Products are shipped or consumed - Manual adjustments are made

Cross-Module Integration: Inventory data integrates with: - Orders: Automatic allocation and availability checking - Receiving: Direct inventory updates from inbound shipments

- Shipping: Real-time quantity adjustments during fulfillment - Reporting: Historical and current inventory analytics

User Permissions¶

View Access: All users can typically view inventory information Edit Access: Inventory modifications require specific permissions Administrative Access: Warehouse status changes require admin privileges

Last Updated: August 2025

Version: 1.0

For additional assistance or feature requests, please contact your system administrator or refer to the complete Zora Tech Logistics Platform documentation.