Order Processing User Guide¶

Table of Contents¶

- Overview

- Accessing Order Management

- Creating Orders

- Viewing Order Details

- Order Fulfillment

- Order Status

- Advanced Features

- Best Practices

- Troubleshooting

Overview¶

The Order Processing system in Zora Tech's Logistics Platform manages the complete fulfillment workflow from order receipt through shipment. This comprehensive module enables efficient order creation, allocation, picking, packing, and shipping operations.

Key Features¶

- Multi-channel order creation: Manual entry, bulk import, and API integration

- Intelligent inventory allocation: Automatic FIFO-based allocation with manual override options

- Complete fulfillment workflow: Pick, pack, and ship operations with barcode scanning

- Real-time status tracking: Monitor order progress through each fulfillment stage

- Customer management integration: Seamless customer and address management

- Warehouse context: Filter and manage orders by warehouse location

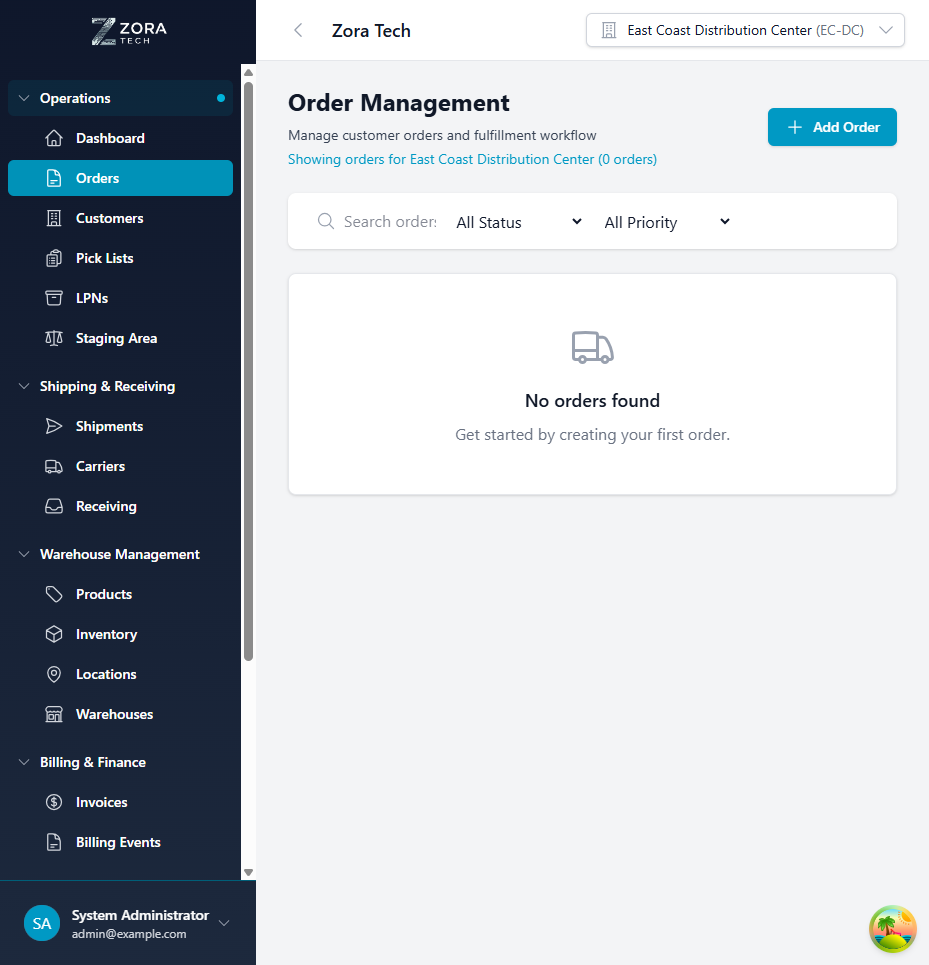

Accessing Order Management¶

Step 1: Navigate to Orders¶

- In the left sidebar, locate the "Operations" section

- Click on "Orders"

- You'll see the order management page displaying:

- List of all orders with key details

- "Add Order" button for creating new orders

- Filter options for status and priority

- Search functionality for finding specific orders

- Sortable columns for order details, customer info, and status

Order List Features¶

The order listing page provides a comprehensive view of all orders:

Search and Filtering¶

- Search: Find orders by order number, customer name, or email

- Status Filter: Filter by Draft, Pending, Allocated, Picking, Picked, Shipped, etc.

- Priority Filter: View orders by Low, Normal, High, or Urgent priority

- Warehouse Context: Automatically filtered to your selected warehouse

Order Information Display¶

- Order Number: Unique identifier (e.g., ORD-20251118-001)

- Order Date: When the order was created

- Customer Information: Customer name and contact email

- Items & Total: Number of line items and order total value

- Status Badge: Color-coded current order status

- Priority Indicator: Visual priority level display

Creating Orders¶

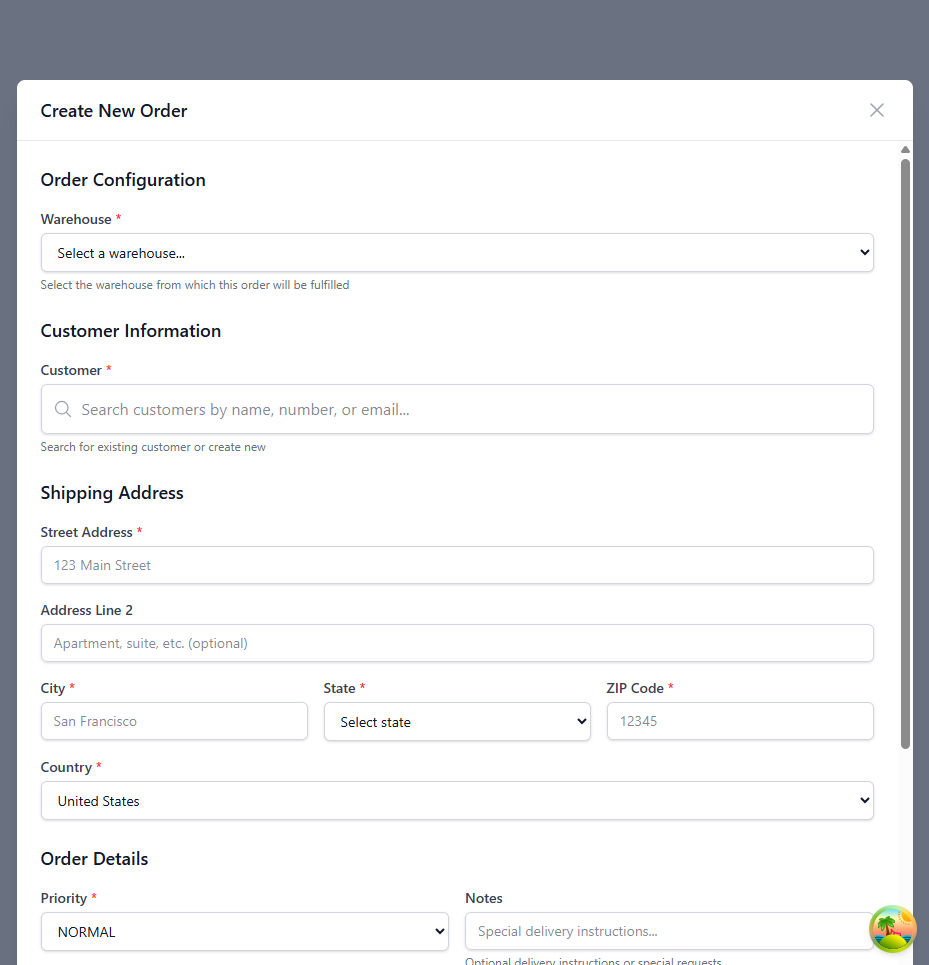

Manual Order Entry¶

Step 2: Initiate Order Creation¶

From the Orders page, click the "Add Order" button to open the creation form.

Step 3: Complete Order Information¶

Order Configuration (Required)¶

- Warehouse:

- Select the warehouse from which this order will be fulfilled

- Determines available inventory for allocation

- Filters applicable locations and staging areas

Customer Information (Required)¶

- Customer Selection:

- Search by customer name, number, or email

- Select existing customer or create new

- View customer details including tier, status, and available credit

Shipping Address (Required)¶

- Address Selection:

- Choose from customer's saved addresses

- Addresses are pre-populated from customer records

- View delivery instructions and contact information

- Option to add new address if needed

Order Details¶

- Priority (Required):

- LOW: Standard processing time

- NORMAL: Default priority level

- HIGH: Expedited processing

-

URGENT: Immediate attention required

-

Notes (Optional):

- Special delivery instructions

- Internal handling requirements

- Customer-specific requests

Order Items (Required)¶

- Product Selection:

- Search products by name, SKU, or barcode

- Universal search across all product fields

-

Real-time product availability display

-

Quantity (Required):

- Set quantity for each line item

- System validates against available inventory

-

Supports decimal quantities for certain product types

-

Unit Price (Optional):

- Override default product pricing if needed

- Used for special pricing scenarios

- Calculated automatically from product catalog

Step 4: Submit and Verify¶

- Review all entered information for accuracy

- Ensure at least one product line item is added

- Click "Create Order" to submit the form

- The system will:

- Validate all required fields

- Check inventory availability

- Create order with PENDING status

- Return to order listing page

Import Orders¶

For high-volume order processing: - Bulk CSV Import: Upload orders in standardized CSV format - API Integration: Connect e-commerce platforms and external systems - Template Downloads: Access pre-formatted templates for data preparation

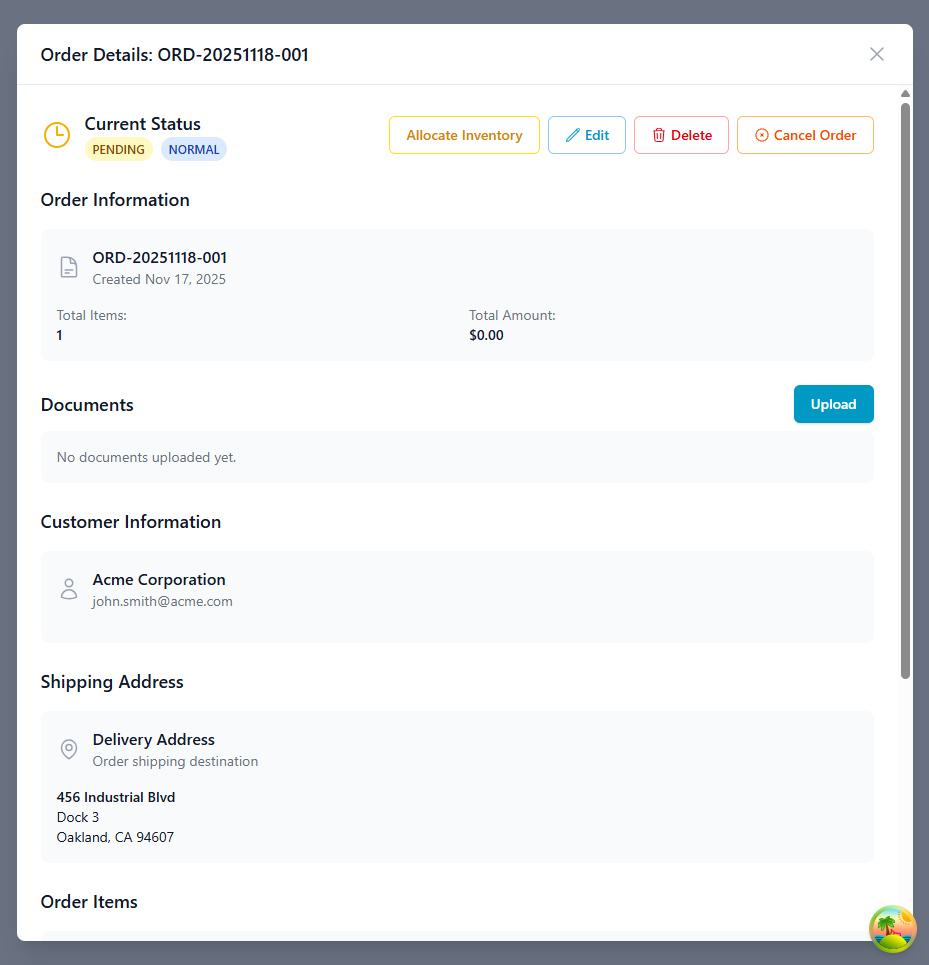

Viewing Order Details¶

Step 5: Access Order Details¶

To view comprehensive information about any order:

- Navigate to the Orders page from the Operations section

- Click on any order row in the table

- The order details modal will open, displaying complete order information

Order Details Information¶

The order details modal provides comprehensive information organized into several key sections:

Current Status Section¶

- Status Indicator: Shows current order status (Pending, Allocated, Picking, etc.)

- Priority Badge: Visual priority level (Low, Normal, High, Urgent)

- Available Actions: Context-sensitive buttons based on order status

- Allocate Inventory: Begin inventory allocation process

- Edit: Modify order details (available for Draft/Pending orders)

- Delete: Remove order permanently

- Cancel Order: Cancel without deletion (preserves history)

Order Information Section¶

- Order Number: Unique system-generated identifier

- Created Date: When the order was first created

- Total Items: Number of unique products in the order

- Total Amount: Calculated order value based on pricing

Customer Information Section¶

- Customer Name: Full customer organization name

- Contact Email: Primary customer email address

- Customer Status: Active/Inactive indicator

- Customer Tier: Enterprise, Standard, or Basic tier level

- Available Credit: Remaining customer credit balance

Shipping Address Section¶

- Delivery Address: Complete shipping destination

- Address Label: Customer-defined address name

- Delivery Instructions: Special handling requirements

- Contact Information: Warehouse contact phone number

Order Items Section¶

For each line item: - Product Name: Full product description - SKU: Product stock keeping unit - Unit Price: Price per unit - Quantity: Ordered quantity - Ordered: Total requested quantity - Allocated: Quantity allocated from inventory - Picked: Quantity successfully picked - Progress Indicators: Visual allocation and picking progress

Documents Section¶

- Document Upload: Attach supporting files (POs, invoices, packing slips)

- Document List: View all attached documents

- Upload Button: Quick access to document management

System Information Section¶

- Created: Original order creation timestamp

- Last Updated: Most recent modification time

- Audit Trail: Complete change history for compliance

Order Fulfillment¶

Pick Workflow¶

- Allocation:

- Click "Allocate Inventory" on pending orders

- System automatically allocates using FIFO strategy

-

Review and adjust allocations as needed

-

Pick List Generation:

- Create pick lists from allocated orders

- System optimizes pick paths based on location

-

Assign to warehouse staff

-

Picking Process:

- Scan products using barcode scanners

- Verify quantities at each location

-

System tracks pick progress in real-time

-

Pick Completion:

- Confirm all items picked

- Move to staging area

- Update order status to "Picked"

Pack Workflow¶

- Packing Station Setup:

- Retrieve picked items from staging

-

Scan items to begin packing process

-

Packaging Selection:

- Choose appropriate packaging materials

- System suggests based on order dimensions

-

Scan packaging for tracking

-

Label Generation:

- Generate shipping labels automatically

- Print carrier-specific labels

-

Attach to completed packages

-

Pack Confirmation:

- Verify all items packed correctly

- Update order status to "Packed"

- Ready for shipping

Ship Workflow¶

- Shipment Preparation:

- Scan packed orders at shipping station

-

Verify carrier and service level

-

Carrier Assignment:

- Select shipping carrier

- Choose service level (Ground, Express, Overnight)

-

System generates tracking number

-

Manifest Generation:

- Create end-of-day manifest

- Include all shipped orders

-

Submit to carrier for pickup

-

Ship Confirmation:

- Mark orders as shipped

- Send tracking notifications to customers

- Update inventory levels

Order Status¶

Understanding order status helps track fulfillment progress:

- Draft: Order created but not yet released for fulfillment

- Pending: Order confirmed, awaiting inventory allocation

- Allocated: Inventory reserved, ready for pick list generation

- Picking: Pick list active, items being retrieved from locations

- Picked: All items successfully picked, ready for packing

- Packing: Items being packed for shipment

- Packed: Packing complete, ready for carrier pickup

- Shipped: Order handed to carrier with tracking number

- Delivered: Customer confirmed delivery receipt

- Cancelled: Order cancelled (inventory released back to stock)

Status Transitions¶

Orders progress through statuses automatically based on actions: - Creating order → Draft or Pending - Allocating inventory → Allocated - Creating pick list → Picking - Completing picks → Picked - Beginning packing → Packing - Generating shipping label → Packed - Carrier pickup → Shipped - Delivery confirmation → Delivered

Advanced Features¶

Wave Picking¶

Batch multiple orders together for efficient picking: - Order Grouping: Combine orders with similar pick locations - Path Optimization: Minimize warehouse travel time - Staff Assignment: Distribute workload across picking team - Performance Tracking: Monitor pick rates and accuracy

Staging Areas¶

Manage order flow through warehouse: - Quality Control Areas: Inspect picked items before packing - Consolidation Zones: Combine partial picks into complete orders - Shipping Staging: Organize packed orders by carrier and route - Exception Handling: Process orders with special requirements

Multi-Warehouse Orders¶

Split orders across warehouse locations: - Inventory Visibility: Check stock levels across all warehouses - Automatic Splitting: System divides orders based on availability - Consolidated Shipping: Combine shipments when possible - Customer Communication: Notify of multiple shipments

Best Practices¶

Order Creation¶

- Verify Customer Information: Confirm customer details before order creation

- Check Inventory Availability: Ensure products are in stock before promising delivery

- Use Priority Correctly: Reserve URGENT for truly time-sensitive orders

- Add Delivery Notes: Include specific instructions for carriers and warehouse staff

Allocation Strategy¶

- FIFO Method: Use First-In-First-Out for perishable or dated products

- Location Optimization: Consider pick path efficiency in allocation

- Reserve Management: Maintain safety stock levels for high-demand items

- Quality Segregation: Allocate from quality-inspected inventory first

Picking Accuracy¶

- Barcode Scanning: Always scan products to prevent picking errors

- Quantity Verification: Double-check quantities for high-value items

- Location Confirmation: Verify pick location matches system direction

- Exception Reporting: Document any discrepancies immediately

Packing Quality¶

- Appropriate Materials: Use proper packaging for product protection

- Weight Verification: Confirm package weight matches expected total

- Label Accuracy: Ensure shipping labels are clear and correct

- Documentation: Include all required packing slips and inserts

Troubleshooting¶

Common Issues¶

Issue: Cannot create order - "Warehouse required" - Solution: Select a warehouse from the dropdown before submitting - Prevention: Always verify warehouse selection in order form

Issue: Customer not found in search - Solution: Create new customer record before order creation - Check: Verify customer name spelling and search criteria

Issue: Product allocation fails - Solution: Check inventory availability in selected warehouse - Verify: Product is active and has available stock - Alternative: Consider multi-warehouse allocation or backorder

Issue: Order stuck in "Picking" status - Solution: Review pick list progress and completion status - Check: Verify all items have been picked and confirmed - Action: Complete or cancel incomplete picks to proceed

Issue: Cannot generate shipping label - Solution: Verify carrier integration and credentials - Check: Ensure shipping address is complete and valid - Retry: Refresh page and attempt label generation again

Issue: Missing order items in details - Solution: Check order line items in edit mode - Verify: Products still exist and are not deleted - Resolution: Contact administrator if data corruption suspected

Getting Help¶

If you encounter issues not covered in this guide: 1. Contact your system administrator or warehouse manager 2. Check system status and network connectivity 3. Review recent system updates or changes 4. Try accessing from a different device or browser 5. Submit support ticket with order number and error details

Integration Notes¶

Order Context¶

- Orders are warehouse-specific and cannot be transferred between warehouses

- Inventory allocation is performed within the selected warehouse only

- Order numbering follows sequential pattern per warehouse

Permissions¶

- Order creation requires standard user permissions

- Order allocation may require inventory management permissions

- Order cancellation may require supervisor approval

- Contact your administrator for permission changes

Data Flow¶

- Orders sync in real-time across all user sessions

- Inventory levels update immediately upon allocation

- Status changes trigger automatic notifications

- Pick lists generate asynchronously for large orders

Last Updated: November 2025 Version: 1.0

For additional assistance or feature requests, please contact your system administrator or refer to the complete Zora Tech Logistics Platform documentation.